AMR-E300 is a collaborative robot engineered to automate material transport and replace manual handling on the factory floor. Equipped with an advanced autonomous navigation system, it intelligently detects and avoids obstacles, moves freely without floor markers, and operates continuously for seamless, uninterrupted productivity.

PRODUCT HIGHLIGHTS

GREAT COST SAVING

- Minimize reliance on manual labor

- Achieve ROI within 6 months

- Enhance operational efficiency and corporate image

USER-FRIENDLY

- Self-deploy and start operation within a single day

- No professional installation or manufacturer commissioning required

- Minimize setup time and costs

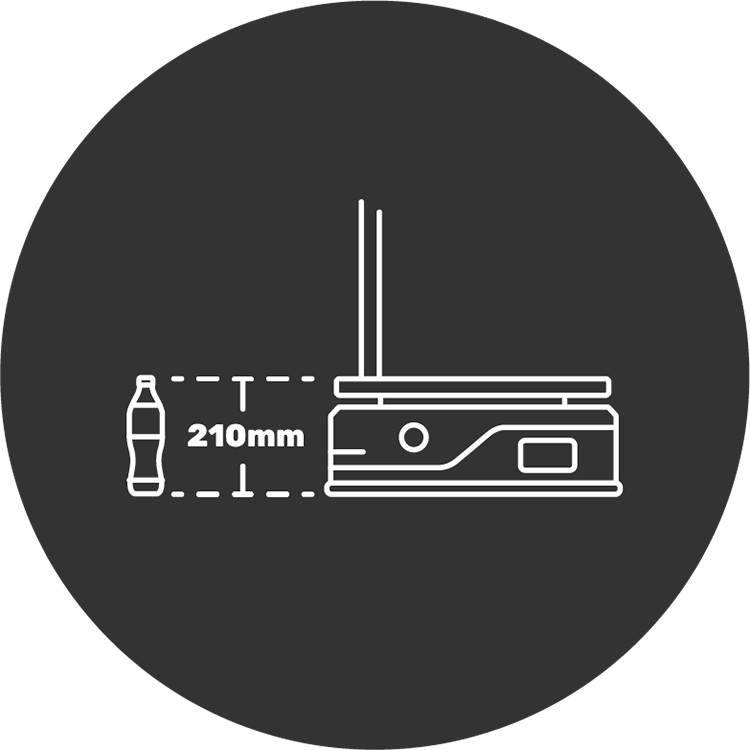

COMPACT & VERSATILE

- Compact chassis height of only 210mm

- Seamless integration with storage cabinets, rack shelves and cargo modules

LONG ENDURANCE

- Advanced battery-swap technology

- Run 24/7 with sub-minute battery replacement

- Also configurable for fully autonomous dock-and-charge operation with no manual intervention required

HIGH STABILITY & ACCURACY

- Powered by precision servo motors

- Exceptionally smooth motion and superior positioning accuracy – even at maximum payload

SAFETY ASSURANCE

- Advanced obstacle avoidance system integrating both laserand vision technologies for enhanced safety and operational reliability

PRODUCT SPECIFICATIONS

| MODEL | STANDARD | LIFT | |

|---|---|---|---|

| BASIC | Product Name | AMR E300 | AMR E300 PRO |

| Navigation Method | Laser SLAM | Laser SLAM | |

| Chassis Type | Two-wheel Differential | Two-wheel Differential | |

| L x W x H | 785 x 470 x 1300mm | 785 x 470 x 1300mm | |

| Rational Diameter | 840mm | 840mm | |

| AMR Weight (Including Battery) | 100kg | 100kg | |

| Maximum Load | 300kg | 300kg | |

| Ground Clearance | 25mm | 25mm | |

| Maximum Lift Height | N/A | 60mm | |

| Temperature and Humidity Range |

Temperature: 0°C to 45°C Humidity: 10% to 90%, Non-condensing |

Temperature: 0°C to 45°C Humidity: 10% to 90%, Non-condensing |

|

| PERFORMANCE | Passability (Slope/Step/Gap) | ≤ 5° / 5 mm / 20 mm | ≤ 5° / 5 mm / 20 mm |

| Navigation Confidence Level | ≥ 70% | ≥ 70% | |

| Minimum Passage Width | 600mm | 600mm | |

| Positional Accuracy | ±10mm | ±10mm | |

| Angle Accuracy | ±1° | ±1° | |

| Navigation Speed | ≤ 1.5 m/s | ≤ 1.5 m/s | |

| BATTERY | Battery Type | Ternary Lithium | Ternary Lithium |

| Battery Specifications | 48V / 15Ah | 48V / 15Ah | |

| Endurance Time | 6h | 6h | |

| Charging Method | Automatic / Manual | Automatic / Manual | |

| Battery Swap Time | < 1 min | < 1 min | |

| Charging Time | < 1.5h | < 1.5h | |

| Cycle Life | ≥ 1000 Times | ≥ 1000 Times | |

APPLICATION SCENARIOS

Engineered for logistics operations, advanced manufacturing hubs, and smart city ecosystems, our robots support modular integration with a wide range of load-bearing units – enabling customized solutions that optimize flexibility and operational efficiency.

STANDARD

E300

Operators manually place the

payload onto the cargo bed.

LIFT

E300 PRO

AMR cargo bed can

automatically lift up a rack.

AUTOMATE YOUR PRODUCTION WORKFLOW TODAY!

Let AMR-E300 handle the heavy lifting while you enjoy significant cost savings and higher productivity. Contact us to map your factory floor.